TURIN, PIEDMONT, ITALY

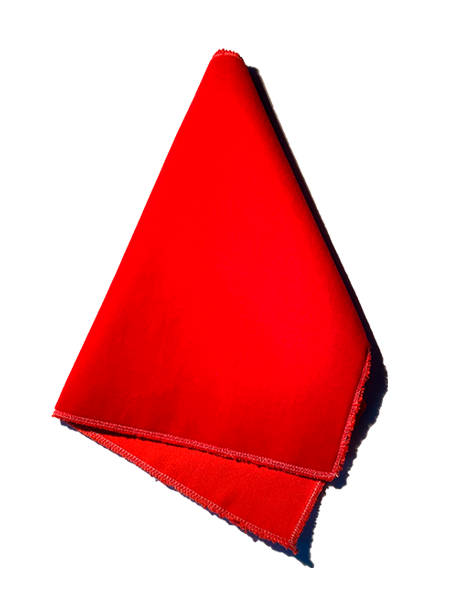

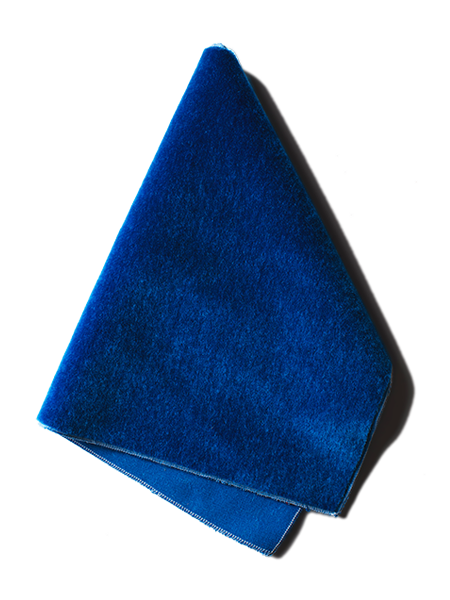

We create, weave, dye and finish

every single meter of velvet

and fabric in order to bring to life

the most prestigious qualities

for textile editors

and international wholesalers.

every single meter of velvet

and fabric in order to bring to life

the most prestigious qualities

for textile editors

and international wholesalers.

Our collection of velvets.

Discover history and qualities of imperfix®, the velvet finishing technology developed by DINOLE®.

EXPERTISE, QUALITY AND PASSION.

DINOLE® is the European leader

in 100% Made in Italy velvets

and fabrics manufacturing.

in 100% Made in Italy velvets

and fabrics manufacturing.

Discover all the shipping steps,

how the integrity of the packaging must be when you receive it

and follow the procedure for the correct storage of DINOLE® velvet.

Watch the video!

how the integrity of the packaging must be when you receive it

and follow the procedure for the correct storage of DINOLE® velvet.

Watch the video!